Linear Guide,LM Guide,Linear Bush,Linear Bearing,Ball Screw,Lead Screw|OZAK SEIKO

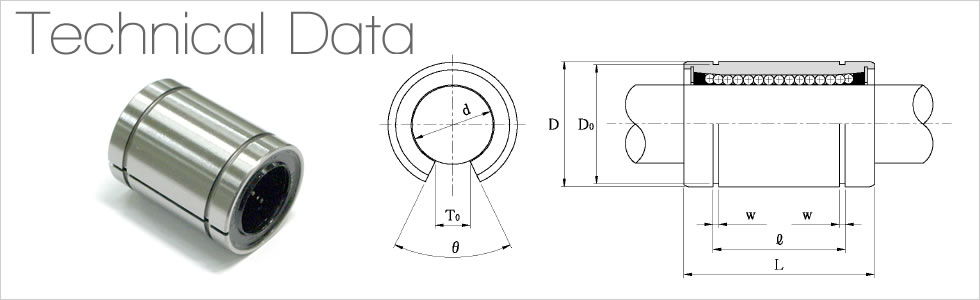

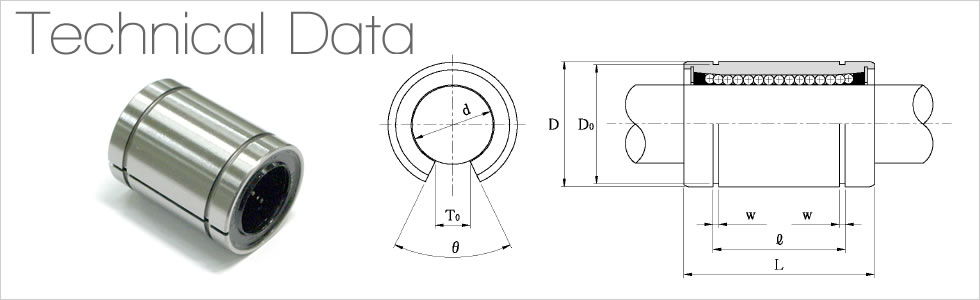

The construction of our linear motion ball bearings, as shown in Fig.1 allows an extremely smooth infinite circulating motion for balls contained in a retainer which is installed inside an outer sleeve. The retainer, fixed by snap rings on both ends, has notch on the part of a circular path, allowing balls in this loaded area to make rolling contact with a shaft, thus obtaining relative displacement under extraordinarily small rolling friction. The guide bearings are best suited for labor saving machinery, automated equipments and energy-saving apparatus etc.

This product is currently accepted for use in various machinery such as electric and mechanical equipment, electronic and semiconductor apparatus, automated machinery, robots, machine tools, measuring instruments, business machines, food and automatic packaging machines, medical instruments, printing machinery, textile-manufacturing equipments, and other general or special industrial machinery.

1.Because of the rolling type contact, both starting and dynamic frictional resistance can be reduced sharply, thus making energy-saving and high speed operations possible with a small power source.

2.The highly reliable guiding mechanism can be used for a long time, because of its long-term precision support capability and low friction loss even under heavy loads without a tangible variation of friction coefficient in relation to an increase in active loads.

3.Once the designer chooses the best selection of linear motion ball bearings for a particular machine, the linear guiding device will work well, regardless of the stroke length.

4.The linear motion ball bearings are 100% interchangeable, making replacement, refurbishing easy.

5.The lighter and smaller machine construction is made possible by the linear motion ball bearings resulting in a compact yet slim linear motion mechanism.

6.It is normally recommended that bearings be used that have both ends sealed; to prevent the lubricating oils from leaking. These grease-mounted bearings with both ends sealed effectively shorten maintenance time.( In one special case, non-sealed bearings are not recommended, however in that case the operating environment is oil free.)

7.Also, the both-end sealed bearings are suitable for use under heavy dust or to prevent possible intrusion of foreign objects.

Standard Type.

The standard type is the most widely used. It is made up of the following two series

L Series : For Metric System ; Japanese specifications.

LE Series : For Metric System ; European specifications.

Sealed Type.

Lip-type, special synthetic rubber sealing is provided on either, one, or both ends of a bearing, designed for such problems as heavy dust or possible intrusion of foreign matter. Also, this type prevents grease leakage out of the bearings.

L-U(sealed on one end), UU(both ends sealed), LE-U, UU ML-UU

Miniature Type.

Coping with the pressing needs of the times, which demand smaller, lighter and shorter products,

this series includes variations of 3, 4 and 5 mm inside diameter bearings.

Non-Rust Type.

Non-Rust type, M series is better quality, and antirust than stainless type, also price is economical than stainless steel.

ML, ML...UU

With Oil Holes Type.

With Oil Holes Type on the outer sleeve can easily and completely lubricate in every ball rows.

L-OH (with sealed), ML-OH(with sealed)

Open Type.

Removing one line portion of balls, the open type creates a guiding mechanism with high rigidity, while preventing axial deflection.

The open type is similar to our adjustable clearance type. A fitting without play against a shaft can be maintained, while allowing installation of a supporting stand beneath the shaft to avoid deflection.

L-OP, LE-OP

Adjustable Clearance Type.

Equipped with slit in the axial direction on an outer sleeve, a sustained fitting condition without looseness can be obtained, after being installed into a housing where the inside diameter can be adjusted.

L-ADJ, LE-ADJ

Maintenance free Type.

For long life, grease enclosing and dust-proof type is the best. (patented product)

There is all around a special seal, and it is excellent in dustproof and the oil supply.

L-MF, ML-MF